Differences Between Hydraulic and Mechanical Technologies in Automotive Aftermarket Product Manufacturing

In the competitive world of automotive aftermarket manufacturing, technology plays a pivotal role in product design, performance, and reliability. Two primary systems dominate this landscape: hydraulic and mechanical technologies. Understanding the differences between these two can help suppliers, distributors, and mechanics make informed choices about product compatibility, quality, and end-user satisfaction.

Hydraulic systems use fluid pressure to transmit force, offering smooth and precise control, especially in components like clutch and brake systems. Mechanical systems, on the other hand, rely on physical linkages such as cables or rods, making them simpler but often less refined in operation.

As automotive technology continues to evolve, the aftermarket must keep pace with innovations. By comparing hydraulic and mechanical technologies across multiple parameters, we uncover the critical differences that affect product performance and customer satisfaction.

Overview of Hydraulic and Mechanical Systems

Hydraulic and mechanical systems represent two distinct engineering approaches for transferring force in automotive components. Each has its unique characteristics, benefits, and use cases.

– Hydraulic Technology:

– Based on fluid dynamics, using liquids (e.g., hydraulic oil) to transmit power and pressure. Components like pumps, valves, and cylinders convert and control energy.

– Power transmission relies on the incompressibility of fluids, adjusting force magnitude and direction via pressure changes.

– Typical Applications: Braking systems, hydraulic shock absorbers, vehicle lifts.

– Mechanical Technology:

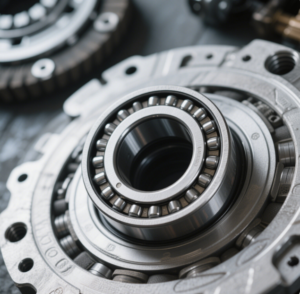

– Based on solid mechanics, transmitting force and motion through rigid components (gears, levers, bearings, chains).

– Power transfer depends on physical contact between parts (e.g., gear meshing, linkage mechanisms).

– Typical Applications: Manual transmissions, mechanical clutches, belt-driven systems.

Hydraulic systems typically include a master cylinder, slave cylinder, and fluid lines. They are closed-loop systems that require high-quality materials such as EPDM rubber seals and corrosion-resistant metals to maintain performance under pressure. Mechanical systems rely on mechanical advantage and wear-resistant materials to maintain longevity, but are prone to increased friction and fatigue over time.

Hydraulic systems typically include a master cylinder, slave cylinder, and fluid lines. They are closed-loop systems that require high-quality materials such as EPDM rubber seals and corrosion-resistant metals to maintain performance under pressure. Mechanical systems rely on mechanical advantage and wear-resistant materials to maintain longevity, but are prone to increased friction and fatigue over time.

Application in the Automotive Aftermarket

In the aftermarket industry, both technologies coexist depending on the age and model of the vehicle, regional preferences, and price sensitivity.

Most modern passenger vehicles have shifted to hydraulic clutches and brakes, while some entry-level or commercial vehicles still use mechanical systems due to cost or simplicity.

Our factory specializes in hydraulic products such as clutch master cylinders, clutch slave cylinders, and concentric slave cylinders. These parts serve high-demand global markets where performance and reliability are paramount. With over 90% of our exports going to Europe, South America, the Asia-Pacific, and Russia, our products are designed to meet or exceed OEM specifications.

Pros and Cons

– Hydraulic Advantages:

– High, adjustable force output.

– Flexible layout (power via pipelines).

– Overload protection (pressure relief valves).

– Hydraulic Drawbacks:

– Leakage risks and environmental concerns.

– High maintenance (fluid/filter replacements).

– Performance drops in extreme temperatures.

– Mechanical Advantages:

– Simple, durable, low maintenance.

– High efficiency and rapid response.

– Longevity in stable conditions.

– Mechanical Drawbacks:

– Wear under heavy loads; frequent lubrication.

– Limited speed control flexibility.

– Bulkier for equivalent power.

Hydraulic technology reduces the risk of product failure in extreme conditions. • Our hydraulic clutch systems provide superior sealing, pressure control, and durability. • Aftermarket customers trust hydraulic solutions for long-term reliability. • Our production meets international standards using digital MES and ISO-certified processes.

Conclusion:

Hydraulic and mechanical technologies each serve a purpose in automotive part manufacturing, but hydraulic systems are increasingly preferred in the modern aftermarket due to their advanced performance, safety, and user comfort. As a specialized manufacturer with three decades of hydraulic expertise, we remain committed to delivering cutting-edge solutions that support the evolving needs of global markets. For businesses seeking reliable, high-quality hydraulic clutch systems, our factory offers a trusted partnership backed by technical innovation and proven results.