Custom Drive Shaft Manufacturing

Why choose TRANSMITEK for Custom Drive Shafts?

- 29 Years of Manufacturing Expertise

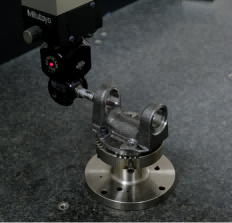

- In-house R&D and CNAS-Certified Testing Laboratory

- ISO/ATF16949 Certified Production Processes

- Custom Driveshaft Solutions for Automotive Aftermarket & Special vehicles such as Passenger Cars, Off-Road, suv,racing, crossovers,sport utility vehicles,Light commercial vehicles, and some agricultural mechinery.

- Serving 100+ Global Brands in 60+ Countries.

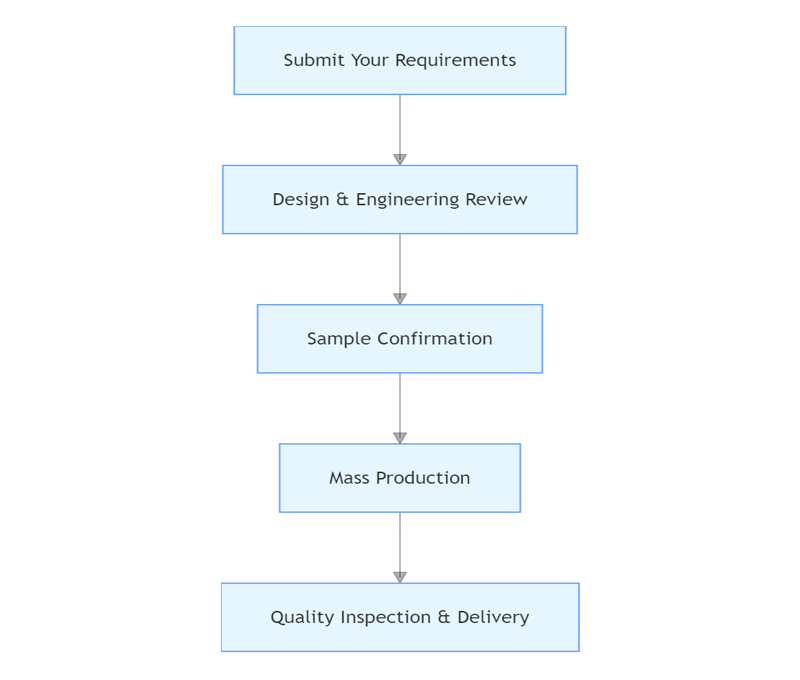

Brief flow chart

How it works?

- Design & Engineering – Engineers analyze torque, power, and suspension specs, then use CAD software to create a design with the right length, diameter, and joint type (U-joints or CV joints).

- Choose Material – High-strength steel, aluminum are chosen based on durability, weight, and cost.

- Cutting,Welding & Assembly – Components cutting, then welded together with high accuracy to ensure structural integrity.

- Balancing – Each driveshaft is dynamically balanced using high-tech machines to eliminate vibration and ensure smooth performance at all speeds.

- Quality Control – Rigorous inspections verify dimensions, alignment, and balance before approval.

- Finishing – Protective coatings (e.g., powder coating) are applied to resist corrosion.

- Testing – Torque and vibration tests, plus test-fitting, ensure optimal performance.

- Delivery – The finished driveshaft is carefully packaged and shipped.

Precision machinery, skilled technicians, and strict quality checks guarantee a high-performance, custom-fit driveshaft.

Our Custom Driveshafts Features

- Built to Fit, Built to Last: Every driveshaft is manufactured to your exact specs—length, diameter, connection types—so it fits your vehicle or equipment like a glove and performs even better.

- Material Choose: We have steel propshaft and aluminum cardan shaft—we pick the right material for your goals,includes its strength, speed, or durability.

- Smooth, Steady, Reliable: Balanced to perfection to eliminate vibrations and reduce stress on other parts. That means a smoother ride and less wear and tear over time.

- Performance: Whether you’re chasing horsepower, hauling loads, or heading off-road—our driveshafts are engineered to handle serious torque and keep power flowing without compromise.

- Less Hassle, More Driving: With fewer breakdowns and lower maintenance needs, our custom driveshafts keep you on the road—and out of the repair shop—longer.

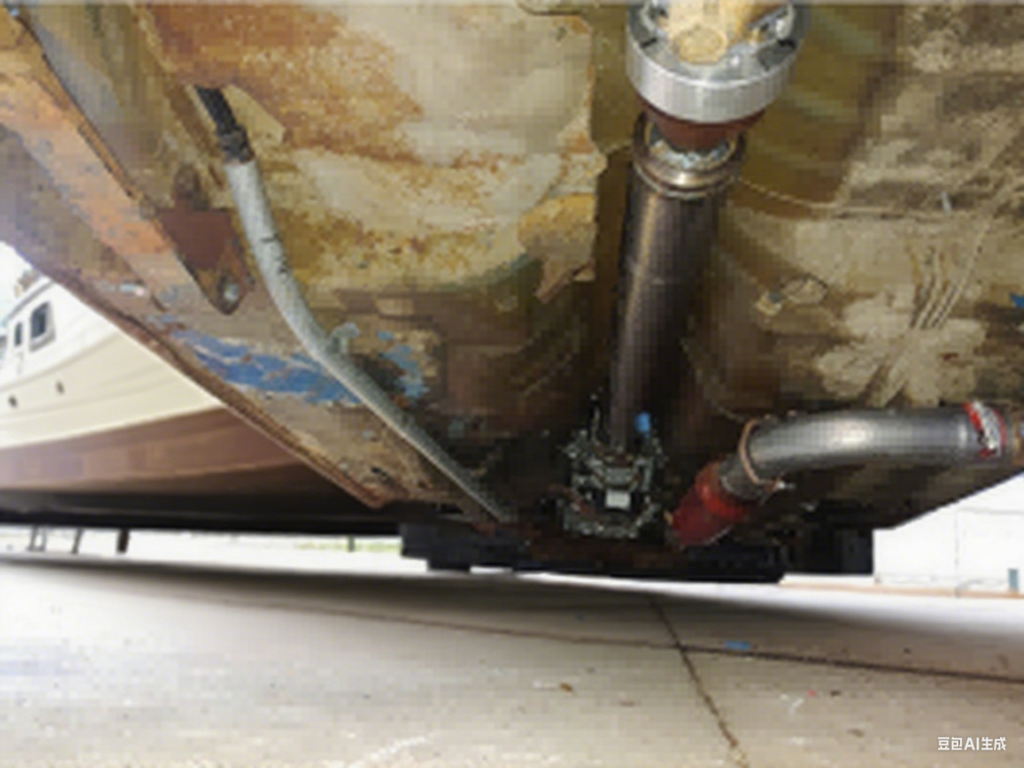

Success Cases

Custom special vehicles

1:European Client – we customized 20 special vehicles for this customer. Some of them are agricultural machinery vehicles, PTO- Shaft for grasshopper…At the beginning, customer ordered 100 units of each model. From 2 orders a year for customized development to 4 orders a year now, 300 units of each model.

2:America vendor – Developed Aluminum shaft, 30% weight reduction and delivered 200 units in 40 days.

3:America importer – Modified Off-Road Vehicles, 30 days developed solution.

FAQ-Frequently Asked Questions

A: For custom drive shafts, MOQ is typically 100 units. Samples are available.

A: Yes, we accept both 2D/3D drawings and physical samples.

We have currently exported to more than 60 countries and regions. In particular export to Europe, North & South America, Asia-Pacific, Russia, and the Middle East.