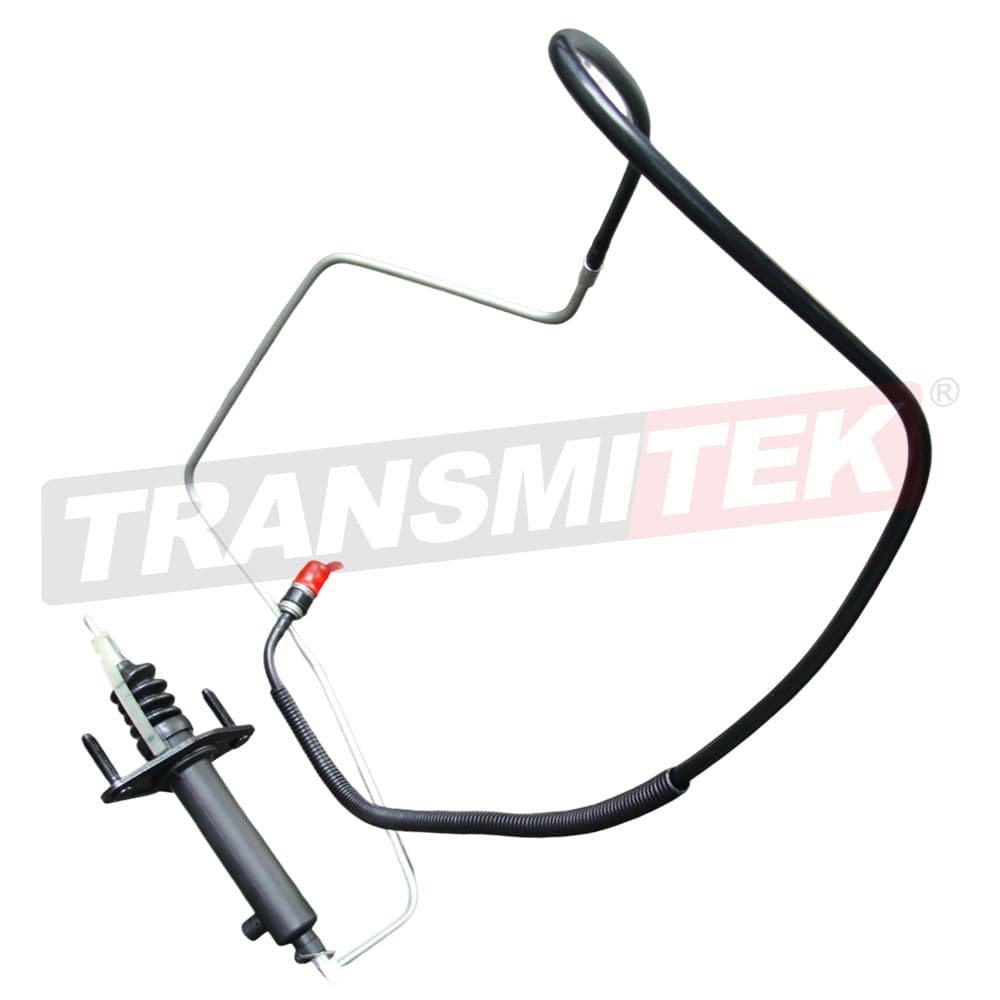

12387711 SL037 Clutch Slave Cylinder

Plastic hydraulic clutch slave cylinders are lightweight, corrosion-resistant components that transfer hydraulic force to disengage the clutch in aftermarket automotive systems.

Quality Guarantee: 2 years or 60,000km

Vehicle suitable For GM BLAZER, For Chevrolet, For GMC

Diameter: φ20.6mm Hole: Φ9.5mm

Replace No.: 12387711,93430139, 12387940, 12549133, 15679653, 15965939, 15659912, 15679690, 15953303, 15998929

SC126874, F126874, SC36005, 12387711, 512-0102-10, 418005410, CS360005

Remark: America market and Mexico market have big demanding for this item.

Description

Definition of Hydraulic Clutch Slave Cylinder

A hydraulic clutch slave cylinder is a key component in a vehicle’s clutch system used in manual transmissions. It is responsible for transferring hydraulic pressure—generated by the clutch master cylinder—to the clutch release mechanism. When the driver presses the clutch pedal, the master cylinder sends fluid through a hydraulic line to the slave cylinder, which then actuates the clutch fork or directly presses the release bearing to disengage the clutch.

Hydraulic clutch slave cylinders are manufactured to replace or upgrade original equipment parts, ensuring smooth clutch operation, compatibility with various vehicle models, and long-lasting performance under diverse driving conditions.

Manufacturing Process of Plastic Hydraulic Clutch Slave Cylinder

Plastic hydraulic clutch slave cylinders are widely used in the automotive aftermarket due to their lightweight, cost-efficiency, corrosion resistance, and ease of mass production. Below is an overview of the complete manufacturing process for plastic-type clutch slave cylinders:

Material Preparation

- Main Material: High-performance plastic such as PA66 (Polyamide 66), often reinforced with glass fiber for added strength and heat resistance.

- Sealing Components: EPDM rubber compatible with brake fluid (DOT3/DOT4).

- All materials are sourced with traceability and tested for thermal and chemical resistance.

Plastic Injection Molding

- Injection Molding Machine melts and injects PA66 into precision-designed molds.

- Molds are cooled and ejected with strict dimensional control (tolerance often within ±0.05mm).

- This step forms the main body of the slave cylinder, including mounting flanges and hydraulic port connections.

Post-Molding Processing

- Trimming of excess plastic or flash from molding.

- Visual inspection for molding defects (bubbles, warping, cracks).

- Drilling and tapping may be applied to the hydraulic port if needed.

Rubber & Metal Component Preparation

- Pistons (usually metal or high-strength plastic), springs, seals, and dust boots are prepared in parallel.

- Rubber parts are molded using heat compression or injection, tested for flexibility and sealing ability.

Sub-Assembly

- The piston is inserted into the molded plastic housing.

- Rubber seals, O-rings, and return springs are assembled.

- Lubricant applied inside to reduce friction and ensure smooth piston travel.

Quality & Leak Testing

- Each assembled unit is tested for: • Air-tightness • Hydraulic performance under pressure • Piston stroke accuracy

- A leak test bench simulates operating pressure (up to 15 bar) to ensure sealing integrity.

Optional Prefilled Assembly

- If required, the slave cylinder is filled with DOT3 or DOT4 fluid in a vacuum environment.

- Air is removed to ensure zero air bubbles for better responsiveness.

Final Inspection

- Functional and dimensional check using gauges or coordinate measuring machines (CMM).

- Surface check to ensure no cracks, molding defects, or leakage.

- Compliance with OEM or aftermarket specifications.

Marking & Packaging

- Product identification via laser marking or pad printing (part number, batch code, etc.).

- Protective end caps are fitted to prevent contamination.

- Packaged in custom boxes with labels and barcodes, suitable for warehouse and export.

Shipping & Storage

- Products are stored in dry, temperature-controlled environments.

- Palletized and exported globally, especially to Europe, South America, and the Asia-Pacific region.

Conclusion

The plastic hydraulic clutch slave cylinder manufacturing process leverages modern injection molding and precision assembly to deliver lightweight, durable, and corrosion-resistant components for the global automotive aftermarket. The use of advanced polymers like PA66 and strict quality controls ensures high performance and cost-efficiency for OEM replacement applications.